Methanisation in 10 questions: a guide from ADEME

May 2018

Agence pour l’Environnement et la Maîtrise de l’Energie (ADEME)

Using waste to produce energy is a mature process but still relatively undeveloped in France, unlike our European neighbours (Germany, Italy, Denmark, etc.), which each have several thousand methanisation units in operation. Methanisation produces biogas from the fermentation of waste, livestock effluents, crop residues, etc. This gas is used to produce heat, electricity and to power vehicles. This technology contributes to reducing France’s energy dependence and to achieving its renewable energy development objectives. It is also a real opportunity at the local level, particularly for farmers and local authorities. Methanisation is still little known in France and raises questions from future residents of methanisation units. This guide provides answers to the 10 most frequently asked questions on this subject.

To download : livret-la-methanisation-en-10-questions.pdf (1.3 MiB)

1 - Why is methanisation essential in France?

Organic waste as an energy resource

Methanisation units of all sizes are being installed in France. They represent a real opportunity, particularly for farmers and local authorities, by enabling them to produce biogas for their own consumption or to sell it, but also to find a solution for organic waste that is transformed into natural fertiliser.

On 1 January 2018, there were 570 methanisation units in France. By 1 January 2022, the number had risen to 1,308 methanisation units, of which 371 are injection units and 759 are cogeneration units.

1 methanisation unit treating 15,000 tonnes/year is equivalent to

-

500 heated houses

-

60 buses fuelled by fossil fuels

1 kWh of biomethane injected into the gas network is equivalent to 200 g of CO2 avoided.

By 2030, the quantities of biomethane injected into the natural gas network could represent 10% of national gas consumption, or 40,000 GWh.

Biogas is part of France’s energy mix

The share of renewable energies should double by 2030 to represent 32% of energy consumption in France. We have many renewable energies on our territory that complement each other to diversify energy production and reduce our dependence on fossil fuels. In particular, France has the largest wind energy potential, the third largest solar energy potential and the fourth largest forest area in Europe. Biogas is becoming increasingly important in the energy mix: by 2030, it should account for 10% of natural gas consumption in France.

Methanisation helps combat climate change

It contributes in two ways to reducing our greenhouse gas emissions. Firstly, because biogas can be used to replace fossil fuels (oil, gas, coal) to heat buildings, run vehicles and produce electricity. Secondly, because the process captures the methane, a powerful greenhouse gas, naturally produced during the decomposition of organic matter, in particular livestock effluents.

Waste is better managed and at lower cost

Methanisers can be used for a wide range of organic waste, including greasy or very wet waste that cannot be composted. This means less waste to incinerate and landfill. The cost of treating waste by anaerobic digestion is around €50 per tonne, compared with around €100 for incineration or for the storage of non-hazardous waste.

Methanisation preserves and creates jobs

Building anaerobic digestion units, organising transport and logistics, and ensuring maintenance require labour. Thousands of jobs should be created in France in the years to come, with the installation of hundreds of sites. Methanisation also makes it possible to perpetuate existing agricultural jobs.

Savings for farmers

Farmers with an anaerobic digestion unit on their farm can use the biogas to produce heat and use it directly on their farm. This reduces their energy bills. By using the digestate to fertilise their crops, they reduce the cost of buying industrial fertilisers. Farmers can also sell all or a surplus of the biogas produced.

2 - How does methanisation work?

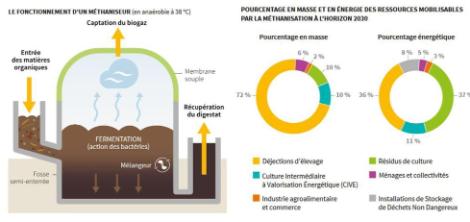

The methaniser transforms organic matter into biogas and digestate

Methanisation uses a natural biological process. In the absence of oxygen and under the effect of heat (38°C), bacteria transform organic matter into methane, called biogas, and a residue, called digestate.

Many organic wastes can be methanised

Today, livestock effluents make up the bulk of methanised materials: manure and slurry provide the bacteria needed to degrade organic matter. However, these effluents must be supplemented by materials containing more carbon, such as crop residues for example, in order to produce sufficient methane.

By 2030, most of the available resources will be agricultural (90%).

3 - What are biogas and digestate used for?

Biogas is a renewable energy source

This gaseous mixture, mainly composed of methane (CH4) and carbon dioxide (CO2), can :

-

be used as a fuel in a boiler to produce heat;

-

power an engine to produce electricity and heat at the same time: this is called cogeneration;

-

be used as a fuel for vehicles: this is called bio Natural Gas for Vehicles (bioNGV);

-

be purified and injected into the natural gas network: this is called biomethane.

Biogas is sometimes used directly by farmers to dry hay or heat a greenhouse, and by local authorities to heat public buildings and run fleets of buses running on bioNGV. Less noisy, these buses are also much less polluting: they emit almost no fine particles and generate 80% less CO2.

4 - Is it a risky installation?

The risks of fire or explosion linked to biogas are very limited

Biogas production is governed by strict regulations and requires precautions. The levels of danger and potential fire and explosion risks associated with biogas are of the same order, or even lower, than those associated with the storage of natural gas and oil. A biogas plant is therefore no more dangerous than a petrol station. As a potentially explosive mixture, biogas requires precautions, but few accidents relating to its storage have occurred in France. From 1992 to 2017, 18 cases of fire and 15 cases of explosion were recorded in France by the Ministry of the Environment, with few consequences for the local population and the environment. The risks mainly concern the personnel working on the methanisation sites. The sites are equipped with gas detectors, fire extinguishers and an access road for the fire brigade. They are also equipped with a biogas destruction system (e.g. a flare).

The risks associated with the digestate are also under control

The risks of ammonia release into the air or water pollution from digestate are controlled by strict rules:

-

the digestate storage pits are covered and ventilated if necessary

-

the agronomic and sanitary quality of the digestate is checked before spreading;

-

the spreading respects the isolation distances from waterways and dwellings;

-

the spreading respects minimum delays before the return of livestock to the spread plots (grasslands);

-

spreading is carried out using techniques that limit ammonia emissions.

5 - Does a methanisation unit emit odours?

Odours can come from the waste before anaerobic digestion

During anaerobic digestion, the waste decomposes in the absence of oxygen, without contact with the ambient air and therefore without odour. At the end of the process, the volatile fatty acids responsible for odours are destroyed: the digestate produced is practically odourless, even when spread on the fields. Many farmers use anaerobic digestion to reduce the odours from the spreading of manure and slurry. Odours can sometimes be emitted during the transport, storage, unloading and loading of organic waste before anaerobic digestion.

Measures are taken to reduce them as much as possible

-

Transport is carried out in sealed trucks.

-

The number of return trips by trucks is reduced to a minimum.

-

Loading and unloading take place in a closed, watertight shed.

-

Trucks are washed or rinsed frequently.

-

The storage buildings are subject to forced ventilation and the stale air is extracted and treated in a deodorisation unit.

To enable the operator to react quickly if unpleasant odours bother local residents, he can also set up surveillance on the site and in the neighbourhood, involving local residents in a ‘nose jury’.

AND FLIES? As the organic matter is stored in a closed and sealed room, flies are not attracted and do not proliferate around the methaniser.

6 - Does a methanisation unit make noise?

Noise emissions from a methanisation unit are minimal

When the anaerobic digestion plant is equipped with a cogeneration unit to produce both electricity and heat, a motor runs continuously. This engine is housed in a soundproof enclosure which reduces the noise to less than 51 dB (the noise level of a washing machine) within a radius of 50 metres. The handling equipment and construction machinery used within the facility also comply with the regulatory limits for noise emissions, i.e. less than 70 dB during the day. They are used during normal working hours, from 8am to 6pm on weekdays.

7 - What traffic is generated by the logistics?

Traffic is optimised and limited to the maximum

A large anaerobic digestion plant (industrial unit) requires the passage of 10 trucks per working day. For a smaller methanisation unit (on the farm), traffic only increases by one truck per day during working hours. Transport is always optimised to reduce distances, limit inconvenience to local residents and reduce fuel consumption. Similarly, the timetables and traffic routes are adapted to avoid peak hours and the busiest areas.

8 - What is its impact on the landscape?

Landscape integration should be taken into account when choosing the site for the methanisation unit. Colours close to those of nature allow the buildings to be better integrated into their environment. Everything is done to make the facility as inconspicuous as possible. To create visual harmony and cause as little disturbance as possible to local residents, several solutions exist, such as the choice of material colours adapted to the surrounding environment, partial burial of storage tanks or digesters, the planting of hedges around the site, etc. Project owners are also strongly encouraged to use an architect with expertise in landscape integration.

9 - How are decisions taken to install a methanisation unit?

There are many potential project owners

-

A farmer or a group of farmers: a methanisation project complements their activity, to make use of livestock effluents and agricultural by-products.

-

A group of farmers, a local authority or a group of citizens as part of a territorial project. Not only does the project make it possible to treat agricultural effluents and waste from the territory, but it also involves citizens.

-

Industries (food, chemical, paper, etc.) to better valorise their waste;

-

Wastewater treatment plants to methanise their sludge;

-

Local authorities to recover organic waste from residents.

A dialogue is established with local residents for a shared project

Project stakeholders and residents must be able to talk to each other. The exchanges, often facilitated by the community hosting the project, take place in 3 stages:

-

stage 1: informing the population ;

-

stage 2: consultation to find out the opinions of inhabitants and users;

-

stage 3: consultation to allow dialogue and seek agreement between all interested parties to launch the project.

Informed about the challenges of anaerobic digestion for their community, reassured about the possible risks and nuisances, consulted about the landscaping and the ways of using the energy produced, etc., the inhabitants often become the first ambassadors of the anaerobic digestion unit.

Several criteria are taken into account when choosing a site

The choice of site is made in consultation with local residents, according to the following criteria

-

respect for the existing living environment, safety and the environment

-

the proximity of organic material deposits, to facilitate logistics

-

opportunities for biogas recovery: proximity of gas, electricity and heat networks, etc;

-

the available floor space.

Authorisations are required

To build a biogas plant, the project owner must take several steps and obtain authorisations. They must :

-

submit a prior declaration to the town hall or obtain a building permit;

-

meet the requirements of the regulations governing Installations Classified for Environmental Protection (ICPE): declaration, registration or authorisation.

-

for volumes processed in excess of 60 tonnes of waste per day, carry out a hazard study, an impact study, a public enquiry and obtain the opinion of the Environmental Authority.

Construction may be prohibited if the facility is located on a listed site, visible from a historical monument, too close to a drinking water catchment area, located in a flood zone, or causes excessive traffic…

Finally, the methanisation units are monitored and controlled. In the event of non-compliance, administrative measures are taken, which can go as far as withdrawing the authorisation to operate the unit.

10 - How does a participatory or citizen project work?

Citizens can participate in a project in two ways:

-

Investing in the capital of the companies carrying the projects, which allows them to be involved in their governance: this is called citizen projects.

-

Financing projects without participating in their governance: this is called a participatory project or participatory financing, sometimes obtained through a « crowdfunding » campaign.

The financial participation of citizens in projects to develop renewable energy is common in Denmark and Germany, where 50% of the renewable electricity production capacity installed between 2000 and 2010 is owned by citizens (11% of which is owned by farmers).

Citizens mobilise to develop their territory

By supporting these citizen projects, citizens can

-

enhance the economic and energy resources of the territories ;

-

promote a collective dynamic of energy transition, in which the inhabitants express themselves and participate in decision-making;

-

strengthen the local integration of renewable energy projects;

-

participate in a project that makes sense for the territory;

-

maintain and create jobs;

-

develop new skills in the region…

At the beginning of 2018, more than 260 citizen projects, both in development and in operation, are listed throughout France.

Sources

To go further

-

Le Méthascope de France Nature Environnement : www.fne.asso.fr/publications/methascope

-

Guide de l’ADEME « Informer et dialoguer autour d’un projet de méthanisation » : www.ademe.fr/sites/default/files/assets/documents/guideinformeretdialoguermethanisation-032018.pdf

-

Site d’information sur les projets susceptibles d’avoir un impact sur l’environnement : www.projets-environnement.gouv.fr/pages/home/